Industrial Automation: The Driving Force Behind Modern Manufacturing

Time: 11月11日 16:01Industry 4.0 is no longer just a concept but has turned into a global digital transformation that is driving manufacturing industries. And the biggest impact of this upgrade is seen in terms of industrial automation technology.

Automation drives faster production cycles, reduces errors, optimizes costs, and improves sustainability, keeping businesses competitive. This has made automation a must in modern manufacturing. Further, improvements in robotics, IoT, AI, and data connectivity have enabled manufacturers to increase efficiency, reduce costs, and improve product quality. 60% of industries have implemented automation in one form or the other by the end of 2024.

From massive automotive plants to smaller electronic assembly shops, manufacturers of all scales are exploring ways to incorporate cutting-edge technologies into their workflows. Let’s take a look at how industrial automation technology is making a difference in manufacturing industries.

What is Automated Manufacturing Technology

Automated manufacturing technologies combine smart software with rugged, powerful hardware, making production faster, safer, and much more precise. In practice, it refers to control systems that handle industrial machinery and processes with minimal human intervention.

Thus, you are outsourcing repetitive or risky tasks to pre-programmed machines that do not tire, have little to no faults, and keep improving by analysing the data generated. The global industrial automation industry is expected to reach USD 378.57 billion by 2030 with a CAGR of 10.8%.

Depending on the type of production, manufacturers opt for one or more of the following:

Fixed Automation: Designed for high-volume production lines where fixed repetitive actions are achieved with dedicated equipment (e.g., automotive assembly lines).

Programmable Automation: Used in industries like CNC machining, where machines can be reprogrammed for either batch or continuous production processes.

Flexible Automation: Used to build highly adaptable production pipelines that are capable of producing varied products without major retooling (e.g., robotic arms with interchangeable tools).

Key Components of Automation Technology for Manufacturing

Automated industrial technologies are made up of the below building blocks:

Robotics: Automated machines programmed to perform specific tasks like assembling, welding, or painting.

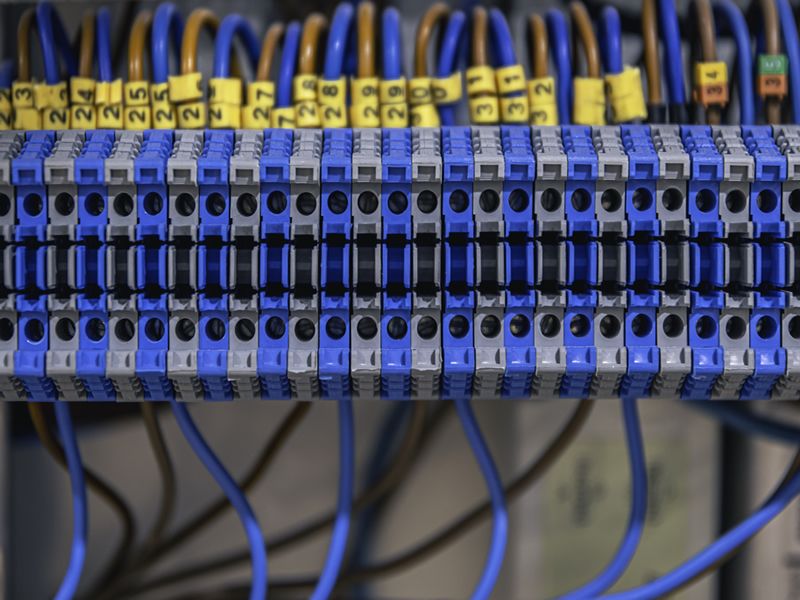

Control System Components: Designed to manage, control, and monitor connected equipment of various operational scale and purpose (e.g., DCS and PLCS units).

Sensors: Devices collecting real-time data on temperature, pressure, position, quality, and other process parameters (e.g., pressure and temperature gauges).

Complementary Functional Layers: These are core mechanical execution elements (electrical, hydraulic, or pneumatic) that use control signals to provide a physical output (e.g., actuators).

Artificial Intelligence (AI) and Machine Learning: Systems that analyze production data to optimize processes and predict maintenance needs.

Industrial Internet of Things (IIoT): Interconnected devices placed on a single network that enable seamless communication and data exchange across machines and systems.

Why Manufacturers Are Investing in Automation Technologies

Alongside efficiency, automated industrial technologies offer the following benefits, making them a necessary investment:

Increased production speed and lower cycle times through consistent, continuous operations.

Notable improvement in product quality and consistency due to reduced human error and variance.

Enabling quick changeovers for scalable, flexible production.

Significant reduction in labor costs by assigning repetitive tasks to automated machinery.

Improved worker safety by using automation for hazardous tasks and reducing human exposure plus workplace accidents.

Tracking equipment health and process variables using real-time monitoring for timely interventions.

Reducing downtime by predicting the ideal time for maintenance through analysis of production patterns.

Optimizing resource use and allocation for sustainability.

Key Automation Technologies Powering the Shift

Industrial Automation Technology is not just a DCS or PLCS unit. Instead, it is an interconnected system of machinery, driven by the following technological evolutions:

Industrial Robotics: Robotic arms and associated equipment, designed to work 24/7 without fail or downtime, to carry out precision tasks such as spot welding, painting, and packaging in production lines.

Industrial Internet of Things (IIoT): Smart industrial sensors that continuously gather granular data on key process parameters for process optimization, real-time monitoring, and predictive analytics.

Artificial Intelligence and Machine Learning: Interpreting and processing large datasets to identify anomalies in the production pipeline, optimize production parameters, and improve the final product quality and output.

Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs): These automate material transport within factories, improving logistics and reducing human intervention.

Additive Manufacturing (3D Printing): Enables rapid prototyping for complex designs, helping manufacturers reduce lead times for product development, alongside offering mass customization.

Implementing Automation in Manufacturing: A Stepwise Approach

From deciding the scope of the project to conducting pilots and rollout, implementing automated industrial manufacturing technologies requires a carefully planned approach:

Step 1: Assess process in your industry that demonstrates potential for automation. This includes tasks that are repetitive, can be tracked with process parameters, or are too hazardous to be done manually.

Step 2: Go through the automated industrial technologies available in the market and weigh their suitability for the specific production process. Then, select a technology that matches your production and scalability requirements.

Step 3: Hire consultants or collaborate with experts who have experience with upgrading existing industries using automation. This will ensure you have a smoother time transition for both legacy and compatible equipment.

Step 4: Train the necessary workforce, your technicians, operators, engineers, and project managers on how to use the upgraded automated manufacturing technology. You can also invest in reskilling and change management programs to ensure easier acceptance among your staff.

Step 5: Do a pilot round to root out any and all potential issues with the newly automated system. You may test these on small batch or continuous production lines before full-scale rollouts which allows adjustments and risk mitigation.

Step 6: Implement the automation technology for manufacturing and continuously gather data regarding production parameters, quality, and volume. Then, use this data to refine processes continuously and plan predictive maintenance.

Case Studies: Successful Real-world Implementation of Automation

Among Industrial Automation Systems, Distributed Control Systems have one of the largest market shares, projected to reach USD 29.19 billion by 2030.

A 2016 survey by PwC on Industry 4.0 revealed that automation has the potential to reduce production cycle times by up to 20-30%, while also reducing operational failures by up to 70%. However, with modern innovations, this data is sure to have improved significantly.

Successful implementation of automation technology for manufacturing for a few key industries has been given below:

Table 1: Cases of successful implementation of automation technologies.

Challenges and Roadblocks Faced by Large-scale Adaptation of Industrial Automation Technology

Despite its advantages, implementing industrial automation technology for manufacturing is not as simple as plug-and-play. Engineers and technicians often have to encounter the following obstacles during the adaptation and roll-out:

High initial capital investment of implementing automation technologies makes it a costly affair for small and medium enterprises (SMEs).

Existing staff may need retraining to work alongside or maintain automated manufacturing technology, creating a temporary skill shortage and resistance.

Integration with modern automation solutions with legacy systems requires major upgrades to the current production system

Increased connectivity through IIoT exposes the manufacturing systems to cyber threats that can potentially disrupt operations or compromise sensitive data.

While none of these challenges stop industries from implementing manufacturing automation technology, addressing these challenges involves careful cost-benefit analysis, strategic workforce development, and a robust cybersecurity infrastructure.

The Future of Automation in Manufacturing: What’s Coming Next

Looking ahead, manufacturing is predicted to evolve with the following trends:

Collaborative Robots (Cobots) that work safely alongside human operators, enhancing flexibility and efficiency without replacing workers.

Edge Computing where data is processed closer to the production line ensuring faster decision-making and reduced latency in automated processes.

Sustainable and energy-efficient automation with smart systems that optimize energy consumption, contributing to manufacturers’ environmental goals and reducing operational costs.

Automation expansion for SMEs with the new modular and cloud-based automation solutions that are designed to lower entry barriers, enabling smaller manufacturers to compete effectively with larger production units.

In Conclusion

Proactive automation of automation technologies is transforming manufacturing by boosting efficiency, quality, and safety. When exploring automation for your plant, start small. Identify the most repetitive or error-prone tasks, trial the right technology, and train your team to embrace the change.

Ready for a Smart Automated Industry?

Are you ready to future-proof your production line? Partner with experts who understand your sector and can guide you through a smooth rollout.

Frequently Asked Questions

Will Implementing Automation Help Me Improve Product Quality?

According to a report by McKinsey & Company, a 50% improvement in product quality can be achieved with the help of industrial automation. This is achieved by removing human errors and proactively detecting and correcting potential defects.

Can Industrial Automation Improve Workplace Safety?

By offering safe stops and enabling machines to handle potentially hazardous or physically demanding tasks, industrial automation reduces the risk of workplace accidents and injuries for human workers.

How Much Cost Reduction Can Industrial Automation Achieve?

Cost reduction achieved by automation will vary with the industry and the extent of adoption. For instance, Ford achieved a 20% increase in production efficiency and a 15% reduction in operational costs with a $1 billion investment in AI-driven automation. Similarly, Airbus’s AI-powered QC reduced defects by 30%.

What is the Role of Data in Automated Manufacturing?

IoT and AI integration in automated systems can be used to gather real-time data on production, machine performance, and quality metrics. These can provide actionable insights, ensuring better decision-making, process optimization, and proactive identification of potential issues.

- Previous:Why Ruggedized Networking Matters: The Case for Hirschmann Industrial Switches

- Next:Wuhan Xieyuan - Comprehensive Valve Solutions from Leading Global Brands

Latest news

-

Uniting for a New Beginning: Planned 2026 New Year Ice & Snow Tour

As the year draws to a close, the company is pleased to announce a New Year team tour scheduled from December 26, 2025 to January 2, 2026, with planned destinations including Harbin and Changbai Mountain.

-

Wuhan Xieyuan Partners with World-Class Instrumentation Brands to Lead Excellence in 2026…

Wuhan Xieyuan – Connecting You with World-Leading Process Instrumentation Brands: Siemens, ABB, Emerson, Honeywell, Yokogawa, Endress+Hauser, Schneider Electric, Rockwell Automation, WIKA, Mitsubishi Electric, Omron

-

GMI and Pepperl+Fuchs Safety Barriers: Reliable Protection for Hazardous Area Automation…

G.M. International and Pepperl+Fuchs Intrinsically safe safety barriers are indispensable components in modern industrial automation, especially suitable for environments with explosive gases, dust, or flammable gases.

-

Beckhoff EtherCAT Terminals: Enabling Seamless Industrial Communication

However, for effective implementation, it is important to have the right networking systems, and this is where Beckhoff EtherCAT Terminals come in.