Beckhoff EtherCAT Terminals: Enabling Seamless Industrial Communication

Time: 11月11日 16:345G, IoT, cloud computing, and AI-aided systems are the drivers behind modern automation and machine integration. However, for effective implementation, it is important to have the right networking systems, and this is where Beckhoff EtherCAT Terminals come in.

Modern industries face a serious challenge in achieving seamless communication between devices. These include a lack of standardization, interoperability issues, scalability, cybersecurity risks, connectivity challenges, power security, and more. To address all of these and more, it is important to have connectivity solutions that are compatible with a range of devices and offer high-speed communication.

Let’s take a look at how Beckhoff EtherCAT terminals simplify machine integration and support modern industrial automation.

Understanding EtherCAT Technology

The EtherCAT is a high-performance industrial Ethernet protocol that allows fast and precise communication between industrial devices. This high-speed protocol is designed for industrial automation, offering greater speed and efficiency compared to traditional Ethernet routes.

Since it offers predictable timing and precise synchronization, it is a crucial component of applications where even minor delays can lead to significant errors. Further, EtherCAT processes data as it travels through each connected device instead of waiting for the data packet to arrive.

EtherCAT has become a game-changer in industrial automation due to:

Superior speed and efficiency

Real-time synchronous control

Cost-effective automation system

Support for various network topologies

Wide range of industrial applications

The advantages offered over traditional fieldbus systems include:

High speed, bandwidth utilization, extremely fast cycle times, and low latency.

Deterministic communication enabling highly synchronized and precise motor control.

Precise synchronization with Distributed Clocks (DC).

Requires a standard Ethernet port, reducing hardware costs.

Increases productivity and seamlessly integrates safety data.

Simplifies cabling, installation, network setup, and maintenance.

Provides robust cybersecurity features.

Highly scalable, supporting a massive number of devices (up to 65,535).

High reliability and self-diagnosis capabilities resulting in cost-effective maintenance.

What Are Beckhoff EtherCAT Terminals?

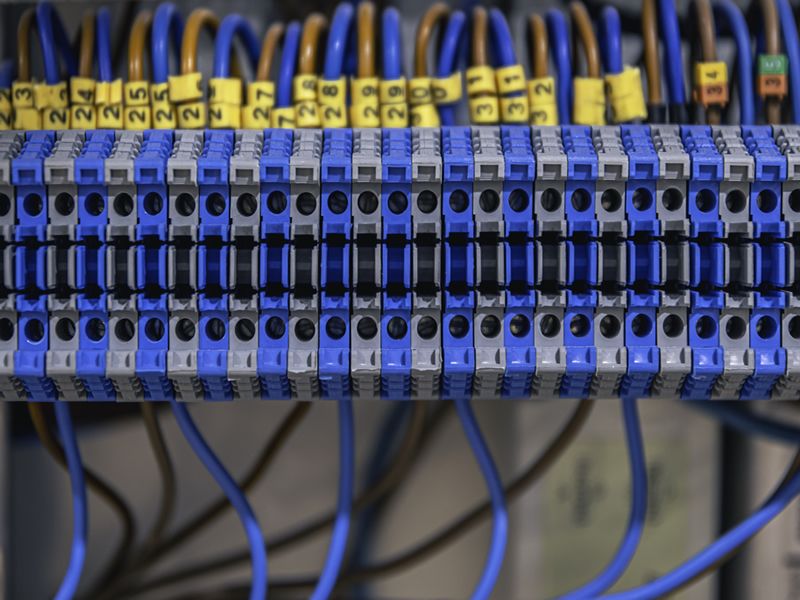

Beckhoff EtherCAT terminals are robust, modular devices that offer industrial automation with a high-speed I/O system. They provide a seamless integration for digital and analog signals, communication gateways, and support certain specialized functions like safety and power measurement.

The key characteristics of Beckhoff EtherCAT Terminals are as follows:

Modular design consisting of individual terminal blocks that can be customized.

High-speed EtherCAT protocol ensures rapid and deterministic data transfer.

Support a broad range of signal types such as digital, analog, communication terminals, and specialized terminals.

Robust construction with durable housings, solid electronics, and secure electrical contacting.

High scalability by supporting more than 65000 devices.

The plug-and-play approach for Beckhoff EtherCAT Modules simplifies integration.

Easy configuration and diagnostics with the Beckhoff EtherCAT Configurator.

How Beckhoff EtherCAT Terminals Simplify Machine Integration

Beckhoff EtherCAT terminals connect with other key components, such as the Beckhoff EtherCAT I/O module. This modular system, integrated hardware, and software like One Cable Technology (OCT) allows the EtherCAT Terminals to offer time-synchronized, high-speed data transfer with a range of network topologies.

The following features help Beckhoff EtherCAT terminals simplify integration and setup:

Compact and robust design of the EtherCAT terminals.

Ease of connectivity, which reduces wiring complexity.

Scalability for easy expansion for future upgrades.

Interoperability by offering compatibility with a wide range of devices and protocols.

Reduced downtime with plug-and-play design and hot-connect/hot-swap features.

Benefits for Manufacturers and Engineers

In industrial applications, these EtherCAT Terminals offer the following benefits:

Improved machine performance with real-time data exchange.

Exceptional performance with reduced CPU load, real-time processing, and control.

Faster commissioning and reduced engineering costs.

Universal communication for the entire plant, simplifying maintenance.

Enhanced flexibility for network structures and customized machine designs.

Cost savings in installation and maintenance due to simplified wiring and openness for interoperability.

High availability and redundancy ensure continuous operation.

Fast diagnostics with rapid error identification and reduced downtimes.

Secure data communication with TwinSafe technology.

Use Cases in Different Industries

The Beckhoff EtherCAT terminals are used for advanced machine control and precise operations in the following industries:

Packaging: high-speed control and modular add-ons.

Automotive: precise control with seamless integration with robotics and assembly lines.

Food and Beverage: adaptability to hygiene and safety compliance.

Semiconductor Industry: wafer coating and automated fabrication.

Process Industry: digitalization, integrated control systems, and functional safety.

Oil and Gas: PLC visualization and functional safety.

Energy: monitoring and control for renewable systems.

Product Handling and Assembly: managing precise movements in robotic and high-throughput systems.

Practical Considerations for Implementation

Though the Beckhoff EtherCAT terminals find uses in multiple industries, it is important to be careful when choosing them. The key considerations to be made are as follows:

Select the right terminal types for your application.

Plan ahead for modular expansions and topological flexibility.

Implement cable redundancy to minimize failure risks.

Choose terminals with the right granularity to meet your system requirements.

Implement diagnostics and safety with TwinSafe technology.

Train the staff to maximize system benefits.

Ensure vendor and support availability for your region.

Future Trends in EtherCAT and Industrial Automation

In 2024, more than 88 million EtherCAT nodes were recorded in industrial applications, claiming wide adaptation. When used in smart industries, EtherCAT plays the following roles:

High-performance real-time communication

Nanosecond-accurate synchronization of network devices

Efficient data acquisition and analysis

Highly flexible and scalable network architectures.

Streamlined maintenance and troubleshooting.

Enhanced productivity and system efficiency.

Cost-effective implementation.

With the use of 5G in industrial communication, EtherCAT-backed networks are overcoming traditional latency and wiring constraints. 5G’s wireless, ultra-low latency design supports EtherCAT’s deterministic control and real-time data processing.

The growth of IIoT and Industry 4.0 also calls for EtherCAT integration, making the push for digital transformation in industries. Further, the modular design and compatibility with existing standard systems ensure that EtherCAT is easily adapted and implemented by industries.

EtherCAT also supports AI-driven predictive maintenance and real-time analytics. The enhanced EtherCAT G and EtherCAT P systems enable faster and more complex data exchange with higher bandwidth solutions.

Key Takeaways

Offering precise synchronization, deterministic communication, high speed, and low latency, Beckhoff EtherCAT terminals streamline machine integration. This makes them a key component for modern industries, helping connect field devices and driving digitization and centralized applications.

Exploring Industrial Solutions by Beckhoff

Ready to implement efficient industrial automation? Explore Beckhoff EtherCAT Terminals and solutions relevant to your specific industry.

- Previous:GMI and Pepperl+Fuchs Safety Barriers: Reliable Protection for Hazardous Area Automation

- Next:Why Ruggedized Networking Matters: The Case for Hirschmann Industrial Switches

Latest news

-

Uniting for a New Beginning: Planned 2026 New Year Ice & Snow Tour

As the year draws to a close, the company is pleased to announce a New Year team tour scheduled from December 26, 2025 to January 2, 2026, with planned destinations including Harbin and Changbai Mountain.

-

Wuhan Xieyuan Partners with World-Class Instrumentation Brands to Lead Excellence in 2026…

Wuhan Xieyuan – Connecting You with World-Leading Process Instrumentation Brands: Siemens, ABB, Emerson, Honeywell, Yokogawa, Endress+Hauser, Schneider Electric, Rockwell Automation, WIKA, Mitsubishi Electric, Omron

-

GMI and Pepperl+Fuchs Safety Barriers: Reliable Protection for Hazardous Area Automation…

G.M. International and Pepperl+Fuchs Intrinsically safe safety barriers are indispensable components in modern industrial automation, especially suitable for environments with explosive gases, dust, or flammable gases.

-

Beckhoff EtherCAT Terminals: Enabling Seamless Industrial Communication

However, for effective implementation, it is important to have the right networking systems, and this is where Beckhoff EtherCAT Terminals come in.